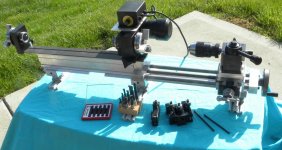

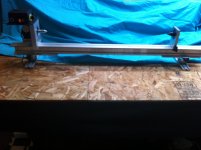

Here are couple of new pictures of th ecoring lathe with a 5/8" keyless chuck. This Lathe has 13" of travel along with a 30" bed, so the total length of the unit is about 46"-47". this unit was designed specifically for coring cues, it could also be customized with an autofeed too.

Along with coring cues, this unit makes a very nice and sturdy high precision Repair lathe too.

I had made 5 units to test the market out, and see whether there is any interest in such a unit.

The Promotion I have been offering customers who inqure about a Cue Building Lathe ll or a Beast Cue Building Lathe is as follows:

instead of getting a loaded beast Cue Lathe @ $4500 Plus shipping.

they can get the Beast Tapering Lathe (with Taig Mill heastock with ER collet) plus the Coring Lathe for $5850. Thanks not all the big bore headstock on the coring lathe is interchangable with the headstock on the beast tapering lathe. Along with those 2 machines comes the cherry on top, which is Buy 2 Get 1 Free. The Free unit is a $450 finishing Lathe

250 RPM Gear Motor with speed control. so th efull package deal would be 3 units for $5850. if those units are purchased seperately the cost would be $4250 + $1800 + $450 = $6500

the same package deal is also offered on the Cue building lathe ll

the price difference is $900 less, @ $4950

Best Regards

Bassel

Custom Cue Lathes

customcuelathes@yahoo.com

248-884-4469

Along with coring cues, this unit makes a very nice and sturdy high precision Repair lathe too.

I had made 5 units to test the market out, and see whether there is any interest in such a unit.

The Promotion I have been offering customers who inqure about a Cue Building Lathe ll or a Beast Cue Building Lathe is as follows:

instead of getting a loaded beast Cue Lathe @ $4500 Plus shipping.

they can get the Beast Tapering Lathe (with Taig Mill heastock with ER collet) plus the Coring Lathe for $5850. Thanks not all the big bore headstock on the coring lathe is interchangable with the headstock on the beast tapering lathe. Along with those 2 machines comes the cherry on top, which is Buy 2 Get 1 Free. The Free unit is a $450 finishing Lathe

250 RPM Gear Motor with speed control. so th efull package deal would be 3 units for $5850. if those units are purchased seperately the cost would be $4250 + $1800 + $450 = $6500

the same package deal is also offered on the Cue building lathe ll

the price difference is $900 less, @ $4950

Best Regards

Bassel

Custom Cue Lathes

customcuelathes@yahoo.com

248-884-4469