Well, first of all I know its possible. Would it be cheaper and better to just spend the money to buy a Cue Companion or similar? I'm tired of having to mail my cues off every time I want some work done and am looking for a solution.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is it possible to build an inexpensive lathe to work on my cues?

- Thread starter Dannydizzan

- Start date

Well, first of all I know its possible. Would it be cheaper and better to just spend the money to buy a Cue Companion or similar? I'm tired of having to mail my cues off every time I want some work done and am looking for a solution.

Wouldn't it be cheaper to just get another shaft? This would be cheaper and you wouldn't have to go without a shaft to shoot with. I wouldn't bother with a cue repair lathe unless you have the extra cash and have allot of patients.

Jim.

Well, I am interested and I am pretty intuitive with woodworking. I could get another shaft, but I'd never learn. Money really isnt the problem, but I dont want to be wasteful and buy something expensive, only to realize that I dont have the patience. I have been interested in cue construction for a couple of years now, but never had the tools. I have acquired quited a few tools now, just dont have a lathe. Also if I had all the work done on all of my cues that needed it, I could but two lathes.

Last edited:

Well, first of all I know its possible. Would it be cheaper and better to just spend the money to buy a Cue Companion or similar? I'm tired of having to mail my cues off every time I want some work done and am looking for a solution.

While I certainly have no idea what your abilities are, however, the average Joe doesn't have the ability to build a machine worth using. In addition the materials to build a machine and the cost of other components that you will need in most cases will cost as much as doing it yourself.

I would look for a good used machine by a quality maker, you should have no trouble finding one.

Good luck and take care.

While I certainly have no idea what your abilities are, however, the average Joe doesn't have the ability to build a machine worth using. In addition the materials to build a machine and the cost of other components that you will need in most cases will cost as much as doing it yourself.

I would look for a good used machine by a quality maker, you should have no trouble finding one.

Good luck and take care.

Yes, I have kept my eyes open on Ebay, but I havent seen many cue lathes lately. I had forgotten about AZ until recently, and I think my luck may be better here.

Yes, I have kept my eyes open on Ebay, but I havent seen many cue lathes lately. I had forgotten about AZ until recently, and I think my luck may be better here.

Send Todd aka tsp&b a p.m he has 3 lathes to pick from. Tsp&b is great guy to deal with too.

While I certainly have no idea what your abilities are, however, the average Joe doesn't have the ability to build a machine worth using. In addition the materials to build a machine and the cost of other components that you will need in most cases will cost as much as doing it yourself.

I would look for a good used machine by a quality maker, you should have no trouble finding one.

Good luck and take care.

Cue Companion is by Unique.

Not by infamous Joe.

Maybe????

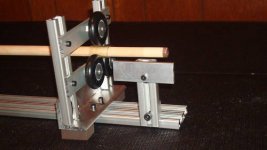

Maybe you can make something like this?

Just to align and spin the shaft?

http://www.ebay.com/itm/PORTABLE-PO...462?pt=LH_DefaultDomain_0&hash=item588dfd66ee

Az Review and troubleshooting :

http://forums.azbilliards.com/showthread.php?t=161901&highlight=cowboy+billiards

Maybe you can make something like this?

Just to align and spin the shaft?

http://www.ebay.com/itm/PORTABLE-PO...462?pt=LH_DefaultDomain_0&hash=item588dfd66ee

Az Review and troubleshooting :

http://forums.azbilliards.com/showthread.php?t=161901&highlight=cowboy+billiards

Attachments

Last edited:

Well, first of all I know its possible. Would it be cheaper and better to just spend the money to buy a Cue Companion or similar? I'm tired of having to mail my cues off every time I want some work done and am looking for a solution.

Good idea......

I did that and now I own a $15,000 cue. (I figure that is what it cost me to build it)

Kim

Good idea......

I did that and now I own a $15,000 cue. (I figure that is what it cost me to build it)

Kim

lol.....

Just like my friend that goes Elk hunting Kim. He invites me over on occasion for $5000 Elk steaks. Can be pretty elusive and he gets skunked 4 out of 5 years, hence the expense.

Todd is a good guy to talk to or check out some of Chuck Peligis's threads. He has a knack for putting together some excellent

repair lathes for personal use. Might get a few ideas from his pics and he would probably help you out as to where parts can be obtained.

Todd will also sell you the parts or at least most of them, but you won't come in much cheaper going that way either. Probably not a huge profit in making lathes and then you'll have to put it together and hope it doesn't schmutz your cue up for you.

Todd is a good guy to talk to or check out some of Chuck Peligis's threads. He has a knack for putting together some excellent

repair lathes for personal use. Might get a few ideas from his pics and he would probably help you out as to where parts can be obtained.

Todd will also sell you the parts or at least most of them, but you won't come in much cheaper going that way either. Probably not a huge profit in making lathes and then you'll have to put it together and hope it doesn't schmutz your cue up for you.

Last edited:

Good idea......

I did that and now I own a $15,000 cue. (I figure that is what it cost me to build it)

Kim

I've done dumber things with my money...

i have owned a few $25,000 cars that were worth $5,000.

chuck

LOL, I had one of those too. Was a lot of fun tho

If you have patience you don't need the lathe. For years I did my own tips with a huge butcher knife and a very steady hand. The knife needs to be razor sharp and hollow ground to work best. You can also use razor blades, but your hand will cramp by the time you're done. Anyways, after gluing the tip and allowing it to cure, stand the shaft up on a cutting board (tip down). Using the knife, shave the excess off one tiny bit at a time. It will take dozens and dozens of cuts, but eventually, you'll get it down to size. Buy extra tips, just in case. After you're done carefully sand any ridges and then burnish. No, it may not be as pretty as a lathe job, but you CAN get it pretty darned close and your cue never leaves the house.

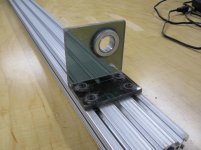

Since this thread seems to be crossing between sanding, finishing, and tipping machines, I thought I would show my old setup (before I got a lathe). It was relatively cheap, and gives you the option of using a Sherline headstock, which sometimes come up on eBay for cheap.

The mounting plate is a Sherline mounting plate which I got from A2ZCNC.com - but I just went to A2ZCNC looking for it and I can't find it - sorry about that.

I also bought a 3/8" tool holder that screws onto the Sherline spindle, but the company I bought that from VCSHobbies.com doesn't seem to stock Sherline parts anymore either. In any case, my maintenance pins have a 3/8" shaft, so I could support the joint end of a shaft using them.

I hand built a Lexan/Plexiglass "tailstock" with a simple bearing mounted in it to hold the tip end using a delrin collet.

I don't claim this particular setup can be used for anything very heavy duty, but it's presented as another option for spinning a cue and how Googling the Internet can help you find alternatives to the stock products.

Hope this helps someone

Gary

The mounting plate is a Sherline mounting plate which I got from A2ZCNC.com - but I just went to A2ZCNC looking for it and I can't find it - sorry about that.

I also bought a 3/8" tool holder that screws onto the Sherline spindle, but the company I bought that from VCSHobbies.com doesn't seem to stock Sherline parts anymore either. In any case, my maintenance pins have a 3/8" shaft, so I could support the joint end of a shaft using them.

I hand built a Lexan/Plexiglass "tailstock" with a simple bearing mounted in it to hold the tip end using a delrin collet.

I don't claim this particular setup can be used for anything very heavy duty, but it's presented as another option for spinning a cue and how Googling the Internet can help you find alternatives to the stock products.

Hope this helps someone

Gary

Attachments

If you have patience you don't need the lathe. For years I did my own tips with a huge butcher knife and a very steady hand. The knife needs to be razor sharp and hollow ground to work best. You can also use razor blades, but your hand will cramp by the time you're done. Anyways, after gluing the tip and allowing it to cure, stand the shaft up on a cutting board (tip down). Using the knife, shave the excess off one tiny bit at a time. It will take dozens and dozens of cuts, but eventually, you'll get it down to size. Buy extra tips, just in case. After you're done carefully sand any ridges and then burnish. No, it may not be as pretty as a lathe job, but you CAN get it pretty darned close and your cue never leaves the house.

Not a bad idea. What do you use now?

I started with this:

http://www.porper.com/index.cfm/fus...487d4da69-4757C438-19B9-F805-2043FBD1FC0D8941

And it worked well, once you spend the time to learn it. Which is the case with any lathe and tools. I suggest getting some bar cues to work on from your local bar, buy a bag of milk duds from muellers, the porper tool, and go to town and learn. If it goes well, then you now have a new way to earn some side income and maintain your own cues . If it goes bad, well you didn't kill either your own shaft, nor anybody elses $$$ shaft either:thumbup:

. If it goes bad, well you didn't kill either your own shaft, nor anybody elses $$$ shaft either:thumbup:

This is the cheapest way to start, and still be able to do a good job without spending $1000's of dollars IMO. And you will still be able to sell the big shaver later to the next beginer in line.

Good luck,

Dave

http://www.porper.com/index.cfm/fus...487d4da69-4757C438-19B9-F805-2043FBD1FC0D8941

And it worked well, once you spend the time to learn it. Which is the case with any lathe and tools. I suggest getting some bar cues to work on from your local bar, buy a bag of milk duds from muellers, the porper tool, and go to town and learn. If it goes well, then you now have a new way to earn some side income and maintain your own cues

This is the cheapest way to start, and still be able to do a good job without spending $1000's of dollars IMO. And you will still be able to sell the big shaver later to the next beginer in line.

Good luck,

Dave

Not a bad idea. What do you use now?

I use a lathe now, but I've tossed the idea around of making cues for 20 years. Last year, I made the plunge.