Over two years ago I posted a thread entitled My "New" GC1 showing off an old table I bought off a friend of mine to go in the unfinished basement of our vacation cabin/retirement home in PA.

(Before shot of table when I brought it in - 1961 GC1)

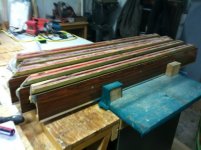

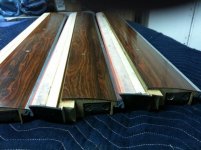

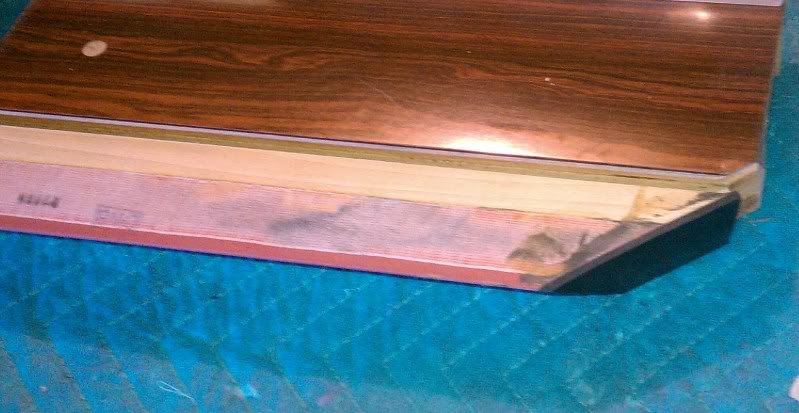

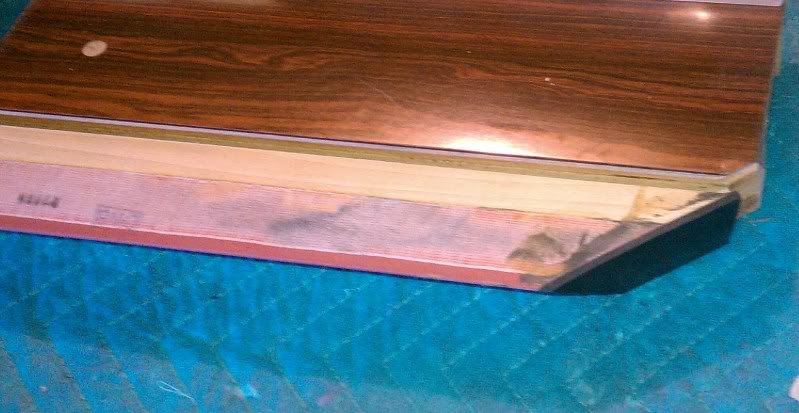

After two+ years of waiting for a mechanic to wander into my neck of the woods, I finally found Bob DeTurk of A Level Above Pool Tables thanks to a post on AZB. Bob was very responsive and after a few phone calls we set up an install date and I dropped off my rails for him to repair. When I dropped them off Bob told me he had a set of rails in better condition that he would substitute for mine.

(finished rail with new extended subrail and new Brunswick Superspeed rubber)

I also had mismatched slates from two different tables that were in rough shape. Bob purchased a new set of GC3 slates just in case we needed them.

A couple of weeks ago, Bob and his assistant Robin made the two hour drive to Shickshinny PA on a Friday morning. They got there about 10AM.

Bob had also had a nice shiny set of adjustable feet from a later model GC1 which he swapped out for my old dull ones.

(Installing the adjustable feet. The last one took a long time to get just right, but they patiently plugged away until it was perfect.)

Next was assembling and leveling the frame. I am very impressed at the solid frame on these old tables.

Robin then spent a long time attempting to level the old slates on the table. It was probably over two hours and ultimately we all realized that they just weren't going to work and I'd have to buy the new slates.

(Attempting to level the old slates.)

(New GC3 slates)

(Sealing the seams.)

Next installment - cloth!

(Before shot of table when I brought it in - 1961 GC1)

After two+ years of waiting for a mechanic to wander into my neck of the woods, I finally found Bob DeTurk of A Level Above Pool Tables thanks to a post on AZB. Bob was very responsive and after a few phone calls we set up an install date and I dropped off my rails for him to repair. When I dropped them off Bob told me he had a set of rails in better condition that he would substitute for mine.

(finished rail with new extended subrail and new Brunswick Superspeed rubber)

I also had mismatched slates from two different tables that were in rough shape. Bob purchased a new set of GC3 slates just in case we needed them.

A couple of weeks ago, Bob and his assistant Robin made the two hour drive to Shickshinny PA on a Friday morning. They got there about 10AM.

Bob had also had a nice shiny set of adjustable feet from a later model GC1 which he swapped out for my old dull ones.

(Installing the adjustable feet. The last one took a long time to get just right, but they patiently plugged away until it was perfect.)

Next was assembling and leveling the frame. I am very impressed at the solid frame on these old tables.

Robin then spent a long time attempting to level the old slates on the table. It was probably over two hours and ultimately we all realized that they just weren't going to work and I'd have to buy the new slates.

(Attempting to level the old slates.)

(New GC3 slates)

(Sealing the seams.)

Next installment - cloth!