Even though I did not ask the question I've always wanted to know this also but never got around to asking. Thanks for the replies !

I do have another question though. out of the small amount of cues that I have some have the matrix on the shafts while others do not. Is this a factor in shaft quality or is the quality usually determined by the grain per inch ?

Thanks

Dennis <---Hoping to learn something

I'm sure we could learn a thing or two from you Dennis :wink:

--------------------------------------------------------------------------------

This grain pattern is "quartersawn" and is characterized by the ray flecks that are circled in your photo. Ray Flecks: Rays, or strips of cells, store food and transport it horizontally throughout the tree. Naturally occuring ray flecks appear as lines across the grain of the wood surface. Hope this helps, Kent

Hi

Please forgive me, but can you please tell me how you can tell by looking at a single dowel, or shaft that it was cut from a flatsawn, or quartersawn board? Once it's turned round there is no difference. Looking at the end of the dowel may give some reference to a dowel cut from a board that was cut from very near the center of the log, vs near the outside.

These Ray flecks, spine,etc, and growth lines are going to show the same on a dowel cut from a board harvested either way.

Dennis <---Hoping to learn something

WHO is this guy, and what does he know about cues :grin:

why do predator shafts use only those pieces?

I was wondering the same thing. On every predator I have owned this pattern has run down each of the ten segments. I always thought that this was the stiffest part of the shaft, and thats why they used it.

It's the radial face of the board, medulary rays are what the lines are called. No matter how the lumber was processed, once turned round, the rays will be evident. Every hardwood in the world has this, not just maple. I & a lot of others call it, "spine", because it looks like the backbone, as stated. It also tends to be the stiffer edges of the wood, which is why quarter & rift sawn lumber is so highly sought after.

Last edited:

If I pick out straight grained shaft dowels how can I tell if they were quarter sawn or flat sawn? For that matter how can you tell how any dowel or square was sawn?

If I pick out straight grained shaft dowels how can I tell if they were quarter sawn or flat sawn? For that matter how can you tell how any dowel or square was sawn?

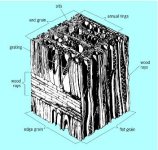

In a dowel, you can't tell. Once turned round there's no way to know how it was milled. In a square, you can have a fair idea if you can see the entire lot. With squares, if the grain runs diagonal on much of, at least half of the lot, then it's been flat sawn. Quarter sawn wood will leave ALL the squares with the grain running parallel to edge. So if you see a pallet of shaft squares & none of the grain runs diagonal across the end grain, then it's a very good chance the wood was quarter sawn.

In quartered lumber, the grain will all run down the face of the board, none on the edge of the board. In flat sawn, most of the boards will have grain running along the edge of the board, some at an angle, and a few out of the center that will be quarter sawn with the grain running down the face. Flat sawn lumber is irregular from board to board where quarter sawn is pretty consistent in grain orientation to the boards.

The major difference with quarter sawn wood and flat sawn wood is stability. With flat sawn, it has to be strapped down in the kiln to keep it from warping, cupping, curling, bowing, twisting, cracking, etc. Once dry it's flat lumber but full of internal stress. This is why it binds & twists when being cut into squares, and moves during the shaft making process. It takes a long time to get them stabilized & even then it's a high waste deal.

Quarter sawn wood is relieved of stress by the cut, before it's dried. It can be stacked & stickered in the kiln with no binding & once dry it's still flat & crack free & stable. I just cut four logs last winter, quarter milled & dried them to 4%, then cut shaft squares & dowelled them. Cutting the boards to squares, then dowelling the squares took a day. That same day I grabbed two random dowels & in one thick, full cut, took them to a 13mm tapered shaft, finish size. That was 2 weeks ago & both shafts are still very much straight. Neither has been hung up. One was laid flat on the concrete floor & the other suspended horizonally over a lathe, resting on the ends with no support undewr the middle 20". I have no doubt in the world that quarter sawn wood makes the most stable & stress free shafts. I have proven that to myself. The entire experiment was to process shafts from trees & knowing everything every step of the way with no questions or doubts about how the wood had been processed because I did it myself. My conclusion was/is that i'll likely never buy another maple board or shaft blank in my life because I haven't found any that left me without doubt. Doing it this way gives me piece of mind.

What a great place this AZ ATC forum is ! Excellent question and knowledgeable answers.

http://en.wikipedia.org/wiki/Medullary_ray_(botany)

Dave <-- loves to learn new things, and thanks all who participate

http://en.wikipedia.org/wiki/Medullary_ray_(botany)

Dave <-- loves to learn new things, and thanks all who participate

I wasn't talking about boards, just well seasoned dowels or individual squares. Five or ten years seasoning is enough to sort out the good from the bad. If they move, they leave.

Quarter sawn wood is relieved of stress by the cut, before it's dried. It can be stacked & stickered in the kiln with no binding & once dry it's still flat & crack free & stable. I just cut four logs last winter, quarter milled & dried them to 4%, then cut shaft squares & dowelled them. Cutting the boards to squares, then dowelling the squares took a day. That same day I grabbed two random dowels & in one thick, full cut, took them to a 13mm tapered shaft, finish size. That was 2 weeks ago & both shafts are still very much straight. Neither has been hung up. One was laid flat on the concrete floor & the other suspended horizonally over a lathe, resting on the ends with no support undewr the middle 20". I have no doubt in the world that quarter sawn wood makes the most stable & stress free shafts. I have proven that to myself. The entire experiment was to process shafts from trees & knowing everything every step of the way with no questions or doubts about how the wood had been processed because I did it myself. My conclusion was/is that i'll likely never buy another maple board or shaft blank in my life because I haven't found any that left me without doubt. Doing it this way gives me piece of mind.

How is the grain orientation on those two? I bet they are perfect .

Quarter sawn wood is relieved of stress by the cut, before it's dried.

There is a reason guitar builders use QS blanks for necks and frets.

They want the best cut out of the tree that has a better chance of staying straighter, longer. Not only the cut but the kiln schedule can make a difference.

<~~~jmo................

In a dowel, you can't tell. Once turned round there's no way to know how it was milled. In a square, you can have a fair idea if you can see the entire lot. With squares, if the grain runs diagonal on much of, at least half of the lot, then it's been flat sawn. Quarter sawn wood will leave ALL the squares with the grain running parallel to edge. So if you see a pallet of shaft squares & none of the grain runs diagonal across the end grain, then it's a very good chance the wood was quarter sawn.

In quartered lumber, the grain will all run down the face of the board, none on the edge of the board. In flat sawn, most of the boards will have grain running along the edge of the board, some at an angle, and a few out of the center that will be quarter sawn with the grain running down the face. Flat sawn lumber is irregular from board to board where quarter sawn is pretty consistent in grain orientation to the boards.

The major difference with quarter sawn wood and flat sawn wood is stability. With flat sawn, it has to be strapped down in the kiln to keep it from warping, cupping, curling, bowing, twisting, cracking, etc. Once dry it's flat lumber but full of internal stress. This is why it binds & twists when being cut into squares, and moves during the shaft making process. It takes a long time to get them stabilized & even then it's a high waste deal.

Quarter sawn wood is relieved of stress by the cut, before it's dried. It can be stacked & stickered in the kiln with no binding & once dry it's still flat & crack free & stable. I just cut four logs last winter, quarter milled & dried them to 4%, then cut shaft squares & dowelled them. Cutting the boards to squares, then dowelling the squares took a day. That same day I grabbed two random dowels & in one thick, full cut, took them to a 13mm tapered shaft, finish size. That was 2 weeks ago & both shafts are still very much straight. Neither has been hung up. One was laid flat on the concrete floor & the other suspended horizonally over a lathe, resting on the ends with no support undewr the middle 20". I have no doubt in the world that quarter sawn wood makes the most stable & stress free shafts. I have proven that to myself. The entire experiment was to process shafts from trees & knowing everything every step of the way with no questions or doubts about how the wood had been processed because I did it myself. My conclusion was/is that i'll likely never buy another maple board or shaft blank in my life because I haven't found any that left me without doubt. Doing it this way gives me piece of mind.

hell of a post brother, very well explained. I don't know if you guys realize but that was golden info right there....

In a dowel, you can't tell. Once turned round there's no way to know how it was milled. In a square, you can have a fair idea if you can see the entire lot. With squares, if the grain runs diagonal on much of, at least half of the lot, then it's been flat sawn. Quarter sawn wood will leave ALL the squares with the grain running parallel to edge. So if you see a pallet of shaft squares & none of the grain runs diagonal across the end grain, then it's a very good chance the wood was quarter sawn.

In quartered lumber, the grain will all run down the face of the board, none on the edge of the board. In flat sawn, most of the boards will have grain running along the edge of the board, some at an angle, and a few out of the center that will be quarter sawn with the grain running down the face. Flat sawn lumber is irregular from board to board where quarter sawn is pretty consistent in grain orientation to the boards.

The major difference with quarter sawn wood and flat sawn wood is stability. With flat sawn, it has to be strapped down in the kiln to keep it from warping, cupping, curling, bowing, twisting, cracking, etc. Once dry it's flat lumber but full of internal stress. This is why it binds & twists when being cut into squares, and moves during the shaft making process. It takes a long time to get them stabilized & even then it's a high waste deal.

Quarter sawn wood is relieved of stress by the cut, before it's dried. It can be stacked & stickered in the kiln with no binding & once dry it's still flat & crack free & stable. I just cut four logs last winter, quarter milled & dried them to 4%, then cut shaft squares & dowelled them. Cutting the boards to squares, then dowelling the squares took a day. That same day I grabbed two random dowels & in one thick, full cut, took them to a 13mm tapered shaft, finish size. That was 2 weeks ago & both shafts are still very much straight. Neither has been hung up. One was laid flat on the concrete floor & the other suspended horizonally over a lathe, resting on the ends with no support undewr the middle 20". I have no doubt in the world that quarter sawn wood makes the most stable & stress free shafts. I have proven that to myself. The entire experiment was to process shafts from trees & knowing everything every step of the way with no questions or doubts about how the wood had been processed because I did it myself. My conclusion was/is that i'll likely never buy another maple board or shaft blank in my life because I haven't found any that left me without doubt. Doing it this way gives me piece of mind.

My post was only intended to point out that no one can really tell by looking at an already turned dowel, or shaft, whether it was cut from a flat or quartersawn board.

Thank you,

Dennis