dakota

Different strokes for different folks.

You can get Juma rods and experiment with them.

If you do, make some mock-ups/jigs in Delrin or UHMW. That way you can tell how you like them. I've made a few in white delrin.

I'm settled on one config now. I like bigger tenon than .312.

I still thread them though.

From a good talk with a traveling repairman, I was convinced even more threading is the way to go. Wood expands and contracts. I don't trust press fit ferrules.

From talking to some of the peeps in Singapore ( where it gets really humid ), I've found out one really famous brand who press-fits their ferrules are famous for gaps developing at the bottom of the ferrule due to movement.

I only use 5-minute epoxy now for customers who need to get out fast ( On shafts I did not make .)

Hysol and 3M 24-hour epoxy are about as good as any epoxy for collars and ferrules imo. They wick in on wood ( 5-minute epoxy do not do a good job of that imo ), fill gaps and their bond is absolutely industrial strength. They can hold airplane parts.

Machining and threading your tenon is not the same as using a die. Sorry, a .312 threaded ferrule on a die that requires the OD to be not more than .285 is not the same . 5-minute epoxy to fill that cap makes it even worse. That config will have a different sound.

DZ freely shares his excellent video here.

http://www.youtube.com/watch?v=JVAyMQj1DqI

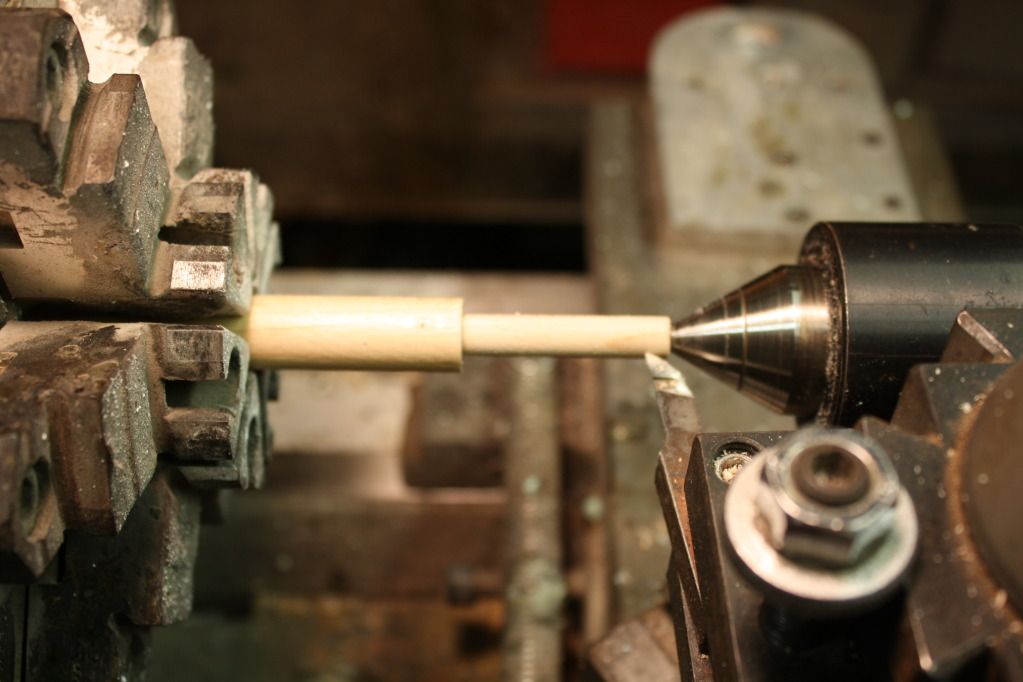

Dave B shows his big tenon ferrules here. .

http://davebarenbrugge.files.wordpress.com/2010/10/003.jpg?w=640&h=480

I do recommend using OB1's carbon fiber on big tenon'd uncapped Juma or on uncapped LBM or Ivor-X or ivory.

Not so on masonmicarta.