Very interesting discussion

Hi,

There are many here with much more cue making experience than I and I don't want to bring up any points on the subject to make an argument but only to interject an opinion based on my observations.

To some, I may be all wet on this subject and if so I am sure that I will here about it. My thing is all about peer check and review and is the basis for my post.

First of all, considering all of the variables lets assume that a pin is inserted and epoxied into the butt with no canting of the pin and is a perfect install with no run out whatsoever.

If the drilled minor dia. is bigger than the body of the pin then the interference between the two should allow the shaft to be inserted and screwed to the butt with a very minimum resistance. Only when the facing occurs will the thread engage to lock the joint.

If the bored hole and the body of the pin are the same dia., then the pin will not work. You must have a compensation or demential gap at the minor. If you are coming to an intersection and are about to crash with another car it does not matter if you avoid the accident by 1 meter or one millimeter. Avoidance of the touching of the dia. of the hole with the body of your pin (less the thread's pitch interface) is the critical factor.

With that being said, I think that the best "Pin / Thread Coverage" occurs when the diameter of the pin is the largest possible for a piece of wood @ about .850 and the pin's threads engage with the most surface area within the shaft with a minimal differential between the hole and the pin's body. The greater the amount of thread area combined with the surface area of the face equals the most joint interface combination which is the ideal.

When we started playing with this to decided which pin would be the best for our cue's design we came to the conclusion to use a modified 3/8 x 14 tpi with a 1.750 Garolite LE insert to be threaded to recieve the pin.

Because of the fact that the wood is a fibrous matter that can weaken or break down over time, the use of an insert that is way over the tensile strength and ductility of wood seems to make the most sense.

( we have all seen the pin to wood joint that is just a small spiral in there from years of use)

Stepping the Diameter:

I have found by stepping the diameter after boring the initial hole gave me the best result. Through trial and error I have reached what I consider to be Nirvana for me in this area. We took a drill tap (see below) and had the drill section ground down to a point the where it was very difficult to screw the cue together without 2 people (4 hands) working the joint. After that we took a standard drill tap and re-tapped the shaft to a certain location point giving stepped minor dia. within the joint.

Now when the cue is put together, the threads get tighter at our stepped intersection and when the facing occurs you can't make it over tighten to stress the pitch area. Getting it just right requires a follow up with a bottom tap to an exact location to get it perfect. It took me a long time to find and be confident with the dimensions associated with that ideal location.

Rick G

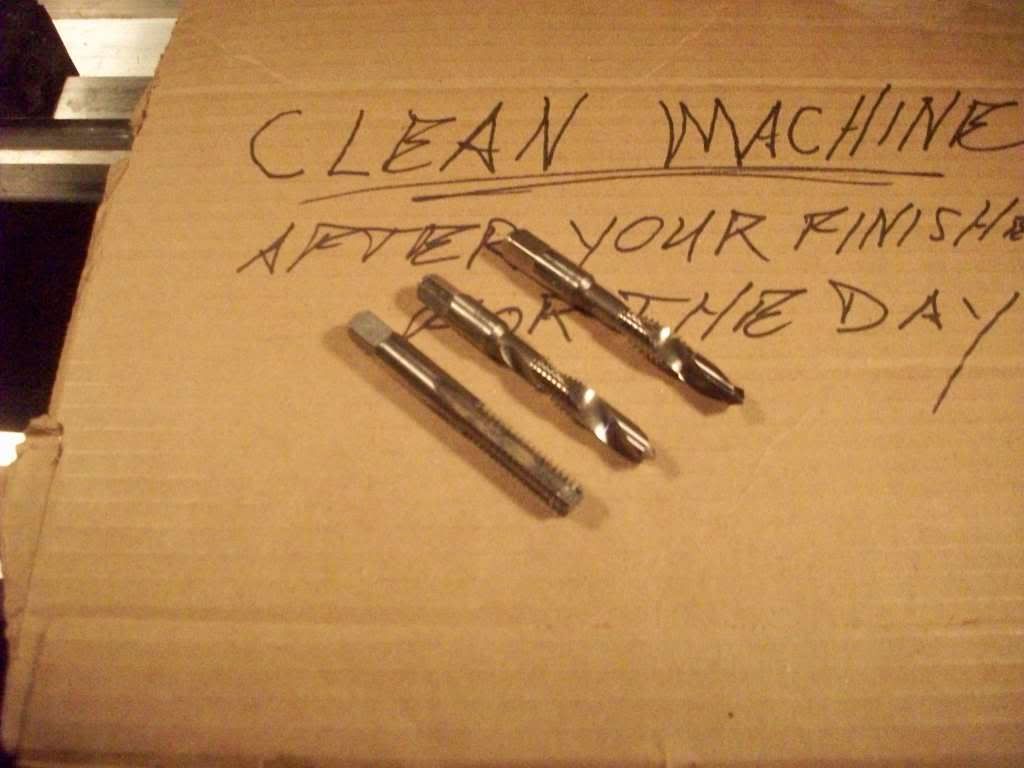

Drill Tap on right has the ground drill dia.

Tap in the middle is standard

Tap on left is the bottom tap

3/8"x14 Tpi Modifed pin with alignment barrel @ .372