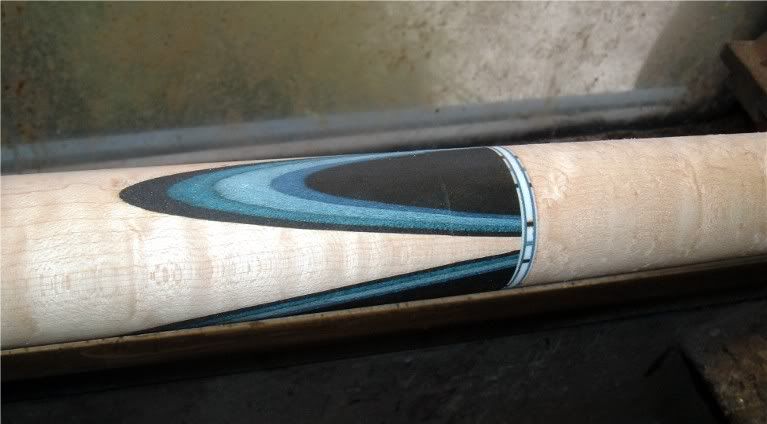

It does seem simple enough, but no it's not that simple. Personally, on the P/J cues I build, the majority of hands-on labor time is spent making rings. Here's a pic of a cue where I showed different ring components:

Notice the billet. It's kingwood with ivory slots. The kingwood cost $25/blank for me to buy. The ring billets for a cue require an entire blank, so in this case I paid $25 for the wood that I was going to use as the ring base. I have to cut that 1.5"x18" square down to 1.35" round & the cut it into 4"-6" sections. I then center drill each section & cut to appropriate size for the billet, which each cue requires 2-3 billets of differing size. Once each section is to size, I have to measure & mark the depth i'm gonna have to make my slots, so I don't go too far & make the rings weak or go too shallow & then the rings fade away while tapering the cue. It's an exacting mathematical science. Now I cut the slots in all the sections & need to cut strips of vory to glue into the slots. I have to cut that ivory exactly perfect & true to fit exactly, and leave excess tallness so I can shave flush to the billet. Ivory isn't cheap, and a mistake in setting up my machinery will be uber expensive. As such, I have dedicated machinery for this process so I get consistent results. By dedicated I mean these machines do only one thing & nothing else. Another huge expense.

Now we have slotted billets made. I'm going to need to accent them with something. In this case, I need more kingwood at $25, a piece of ebony at $35, and some ivory cut round to appropriate size. Ivory costs $300/lb by the way. I now have all my billets & materials ready for making rings. From here I have to cut tenons on the cue & then bore holes in all the billets to fit exactly. Every billet has to have the exact same size bore, or else you get something like what you see in BHQ's picture. Once the holes are bored, I have to then begin parting off rings from the billets. I'm going to have to have my cutter set perfectly and have it super sharp or else my rings won't come out square or clean or the thickness I measured for. Measuring accurately is another task in itself & that requires a jig set up on the ring cutting lathe to measure exact thicknesses for consistent results. More dedicated machines = more money. By the time i'm done with making rings for one cue, I have roughly $100+ in materials and several labor hours in work. I have about $1500 in my dedicated machinery for making & cutting consistent ringwork that carries my signature look. I have failed numerous times while trying to get it all figured out & getting all the kinks worked out. That is aquired skill, not basic skills generally known by all cuemakers.

Sorry for the lengthy post but I wanted to point out that this seemingly simple task is not so simple once you actually do it. To do it correctly & consistently, you have to be enginuitive and willing to spend some money. It's simply not something a newb is capable of. It is advanced cuemaking. While I completely agree anybody can cut some slots, glue in some strips & have slotted ringwork, nobody gets it right the first time...or the second....and only those who put their focus into it are doing it consistently and cleanly. I guess you could always set up a jig for parting rings and buy billets from sources like Prather. But it's still expensive. The expense, time & expertise are why it's not seen on newb cues very often. Hopefully this gives you a less foggy perception of the task of making slotted rings.

I'm not taking any credit from newb builders. I'm simply saying that this kind of work comes from experience, time in the craft.