You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

what is a parabolic taper

- Thread starter deanoc

- Start date

Think of it as a gradual, steadily changing curve. The radius' is not the same anywhere, as opposed to a normal cue with basically a straight section radiused into a tapered section. Snooker cues usually have a conical curve.

Look up parabola,,,,,,probably will be a better explanation than I gave,,,,,,,,,,

Look up parabola,,,,,,probably will be a better explanation than I gave,,,,,,,,,,

Last edited:

posted twice sorry

this has me confused

my concept was before reading(and seeing their picture) mmikes link

was that where most cues slowly get thicker from joint to butt at a steady rate

so that the edge if traced would be a straight line

and the top and bottom if traced would be 2 straight lines forming an angle

a parabolic taper would have areas thicker and thinner as you went from joint to butt

so that a line drawn of the edge would be not be sraight line but "curved"

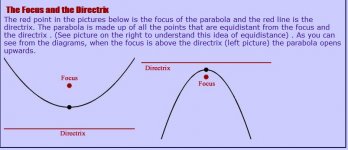

forget about the focus/directrix

the black line is a parabola

the picture on the left where the curve dips the cue would be thinner there (ie around the wrap) that was my concept

is that wrong??

my concept was before reading(and seeing their picture) mmikes link

was that where most cues slowly get thicker from joint to butt at a steady rate

so that the edge if traced would be a straight line

and the top and bottom if traced would be 2 straight lines forming an angle

a parabolic taper would have areas thicker and thinner as you went from joint to butt

so that a line drawn of the edge would be not be sraight line but "curved"

forget about the focus/directrix

the black line is a parabola

the picture on the left where the curve dips the cue would be thinner there (ie around the wrap) that was my concept

is that wrong??

Last edited:

The definition of a parabola is clear, it's how it is applied to a cue taper that might be confusing.

In Mike's link is shows the parabola with the curve facing out...it can also face in.

I do not know how cue makers apply the term or if they all apply it the same way. What surprised me what when I started seeing the term applied to cues as if it were something new. I have two shafts made in the 1970's that have a parabolic taper (opposite type from what Mike posted, the parabolic curves face inward). I always understood that to be a parabolic tapered shaft and never thought there was any other meaning or application unless the term was being applied to the butt. Now I wonder.....

In Mike's link is shows the parabola with the curve facing out...it can also face in.

I do not know how cue makers apply the term or if they all apply it the same way. What surprised me what when I started seeing the term applied to cues as if it were something new. I have two shafts made in the 1970's that have a parabolic taper (opposite type from what Mike posted, the parabolic curves face inward). I always understood that to be a parabolic tapered shaft and never thought there was any other meaning or application unless the term was being applied to the butt. Now I wonder.....

Cue makers use the term parabolic and mudified (not a typo) parabolic taper because it sounds very technical. Until I see someone posting the mathematical formulas they use to generate their curves I am going to guess they arrived at their taper the same way I did. By trial and experimentation with different sizes and tapers.

The use of the term almost always refers to the shaft alone. Butts are 99%+ single or double straight tapers. A conical butt is usually a mistake.

The use of the term almost always refers to the shaft alone. Butts are 99%+ single or double straight tapers. A conical butt is usually a mistake.

Cue makers use the term parabolic and mudified (not a typo) parabolic taper because it sounds very technical. Until I see someone posting the mathematical formulas they use to generate their curves I am going to guess they arrived at their taper the same way I did. By trial and experimentation with different sizes and tapers.

The use of the term almost always refers to the shaft alone. Butts are 99%+ single or double straight tapers. A conical butt is usually a mistake.

I agree 100%. I have never seen anyone reveal their equation and what upper and lower bounds they use for the taper of a cue. Like you said, the term sounds technical and a bit sophisticated. The general equation for a parabola is pretty specific. Not every curved line is parabolic! IMO, the only safe assumption when someone uses the term parabolic to define a cue taper is that it is not strictly linear. Some "parabolic" tapers are likely composed of half a dozen different linear tapers all stacked consecutively. Once final turned and sanded, it is going to look like a curve. Cue/shaft diameters, relative to length, change a very small amount.

Someone mentioned catenary curves in the previous large thread about the term "parabolic".

http://en.wikipedia.org/wiki/Catenary

A catenary curve is derived from a hyperbolic cosine function. Hyperbolic functions are probably as close to describing a pool shaft taper as parabolic functions are. Maybe I should start a new trend and market my shafts as a hyperbolic tapered shaft?

Parabolic is simply a buzz word, and most of the time should not be taken literally, and simply implies nonlinear. This is IMO, of course. I would enjoy someone proving me wrong and posting their parabolic equation they used to cut their taper bar or use on their CNC machine to cut the shaft taper.

Kelly

Last edited:

what is on a house cue

i just don't understand the termonology

thanks

dean

A house cue has a conicical taper - as others have noted, if you trace

the sides of the shaft you would draw two straight lines that

diverge at a constant rate.

The Eiffle Tower - sides are a parabola.

Dale

I agree 100%. I have never seen anyone reveal their equation and what upper and lower bounds they use for the taper of a cue. Like you said, the term sounds technical and a bit sophisticated. The general equation for a parabola is pretty specific. Not every curved line is parabolic! IMO, the only safe assumption when someone uses the term parabolic to define a cue taper is that it is not strictly linear. Some "parabolic" tapers are likely composed of half a dozen different linear tapers all stacked consecutively. Once final turned and sanded, it is going to look like a curve. Cue/shaft diameters, relative to length, change a very small amount.

Someone mentioned catenary curves in the previous large thread about the term "parabolic".

http://en.wikipedia.org/wiki/Catenary

A catenary curve is derived from a hyperbolic cosine function. Hyperbolic functions are probably as close to describing a pool shaft taper as parabolic functions are. Maybe I should start a new trend and market my shafts as a hyperbolic tapered shaft?

Parabolic is simply a buzz word, and most of the time should not be taken literally, and simply implies nonlinear. This is IMO, of course. I would enjoy someone proving me wrong and posting their parabolic equation they used to cut their taper bar or use on their CNC machine to cut the shaft taper.

Kelly

"hyperbolic cosine function"

I won't be able to make a ball for a week.

Dale

The definition of a true parabolic taper and what is refereed to the cue making world are two different Animals. David P. Kersenbrock to my knowledge coined the term Parabolic Taper in cue making sometime during the 1970's and a fairly large number of other cue makers have followed suit using this taper. The most well known of which is South West, Omega DPK, and Bender.

The exact science for the application of the term to cue making I can not break down in simple terms other than the fact that during the process of using this taper the forearm of the finished product is not straight tapered but slightly cone shape toward the cue joint.

Cues that are made using this taper if laid on a flat surface will have the first 2 to 3 inches starting at the joint not touching that surface. This is done by doing a double taper of the cues forearm during the building process. If not done perfectly the cues joint area will wobble if rolled on a flat surface, this is why it is important to closely check any cue that uses this method of construction for roll out at the pin / joint.

The exact science for the application of the term to cue making I can not break down in simple terms other than the fact that during the process of using this taper the forearm of the finished product is not straight tapered but slightly cone shape toward the cue joint.

Cues that are made using this taper if laid on a flat surface will have the first 2 to 3 inches starting at the joint not touching that surface. This is done by doing a double taper of the cues forearm during the building process. If not done perfectly the cues joint area will wobble if rolled on a flat surface, this is why it is important to closely check any cue that uses this method of construction for roll out at the pin / joint.

Stretch a Coca Cola bottle 58 inches, you get parabolic taper for cues.

Joey~Likes in layman terms~:grin-square:

Gotta love those who claim in their for sale ads, " hits like SW " and the cue has one straight taper.

Joey~Likes in layman terms~:grin-square:

Blue Grass, Brick, Klein and Searing among them I think.The most well known of which is South West, Omega DPK, and Bender.

Gotta love those who claim in their for sale ads, " hits like SW " and the cue has one straight taper.

I would enjoy someone proving me wrong and posting their parabolic equation they used to cut their taper bar or use on their CNC machine to cut the shaft taper.

Kelly

This would be like Coca Cola or KFC posting their secret recipes . . . With the proliferation of CNC in the craft, is it really that hard to believe that some are using parabolic tapers? If DPK was doing it 30 years ago, it can certainly be done today. The trick is not sanding off that taper once it's cut.

This would be like Coca Cola or KFC posting their secret recipes . . . With the proliferation of CNC in the craft, is it really that hard to believe that some are using parabolic tapers? If DPK was doing it 30 years ago, it can certainly be done today. The trick is not sanding off that taper once it's cut.

No, but it is hard to believe that everyone who uses the term "parabolic" actually has a true parabolic equation behind their taper bar. The technology used to cut shaft tapers range from CNC to a bar of delrin with screws that are used to create a bend in it, to a lot of sanding to pull back a taper on a shaft blank that is mostly linear. I simply don't think everyone who uses the term parabolic actually used a true parabolic equation to machine their taper bar or shafts via CNC. In the infinitum of nonlinear curves, those derived from a parabola are a tiny subset. But, every shaft taper that has a curve is called "parabolic" (if it is called anything at all). I am a bit of an empiricst, those two statements don't support each other.

In my original post, I used terms like "most of the time" and "only safe assumption". I didn't say nobody has ever used one. Being a nerd, I definitely think it would be a cool thing. If someone thinks their equation is a holy grail akin to Coco Cola's formula, that is cool with me. But, I have seen several cue makers freely share their shaft tapers, ie, diameter measurements every inch or so.

Also, cutting shafts is a bit of an art. The profile of a cut shaft isn't quite identical to the taper bar or the CNC code guiding the cutter.

Kelly

This would be like Coca Cola or KFC posting their secret recipes . . . With the proliferation of CNC in the craft, is it really that hard to believe that some are using parabolic tapers? If DPK was doing it 30 years ago, it can certainly be done today. The trick is not sanding off that taper once it's cut.

How hard would be it to measure a SW and plot it on Mastercam ?

parabolic taper

Man, I thought this horse was long dead. I for one do not use a parabolic taper. I use a compound taper on butt section. Shaft changes at different rate but would be best called a multiple compound. There is no G-Code for a parabolic taper, so cnc has to do a butt load of little G01 or G02/G03 depending which way you are going. A taper bar could be hand ground, but I'd bet it's not a true parabola. Are they majic in cuemaker, I think not, butthey sound like you are using magic. I do believe changing the taper in the cue so it isn't a straight cone is important. How it's done and what they want to call it is up to the individual cuemaker. JMO!

Man, I thought this horse was long dead. I for one do not use a parabolic taper. I use a compound taper on butt section. Shaft changes at different rate but would be best called a multiple compound. There is no G-Code for a parabolic taper, so cnc has to do a butt load of little G01 or G02/G03 depending which way you are going. A taper bar could be hand ground, but I'd bet it's not a true parabola. Are they majic in cuemaker, I think not, butthey sound like you are using magic. I do believe changing the taper in the cue so it isn't a straight cone is important. How it's done and what they want to call it is up to the individual cuemaker. JMO!

This is one area where manual has an advantage over cnc. As was already mentioned It is not that hard to draw a parabolic taper in cad but once in cam in order for the machine to convert your spline into code it is converted into either very short sections of lines or you can convert the spline into many arcs. You can adjust the precision in your cam but your program gets larger as you try and get closer to your drawing. Most controles cant handle it, especially when your dealing with the smaller homebuilt cnc's. It is however not hard to make a parabolic taper with a taper bar. I think the taper on my cues is very close to true. Here is my taper bar and it certainly isnt rocket science.

http://i922.photobucket.com/albums/ad69/legoboy_photo/IMGP2050.jpg

http://i922.photobucket.com/albums/ad69/legoboy_photo/IMGP2050.jpg

... Butts are 99%+ single or double straight tapers. A conical butt is usually a mistake.

Paul, what do you mean by your last sentence? A straight-tapered butt is a truncated cone, right?

How hard would be it to measure a SW and plot it on Mastercam ?

Considerabley more so than analyizing it with a digitizing probe, but

you already know that.

Dale(who has every confidence in Joey)

RBC

Deceased

Paul, what do you mean by your last sentence? A straight-tapered butt is a truncated cone, right?

I think a truncated cone is called a frustom. And yes, that's what the butt of a cue is if it has a single line taper.