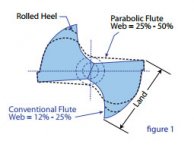

Take a arc segment out of any circle add a focus point and you have a parabola.A 29 inch segment with 60 foot radius can be called a parabola.

in simple G-code

G01 X0 Y0

G02 X29 Y0 R720.00

instant parabola

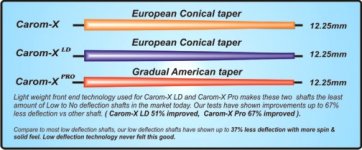

compound tapers are better for shafts to hit pool balls.

parabola works good for mirrors focusing light.

Maybe a parabolic shaft will help you see the balls better.

bill

I did not say the term focus point is in the g-code language.you can take a arc and determine the parabolic focal point.the center point end of the radius is not the parabolic focal point.

bill

I don't quite understand what you are saying... Your first post to me says that its possible to program a parabola with G-code. However, the example you gave is for an arc, with given start point, end point, and radius. It is not a parabola. Am I interpreting you correctly? Thanks.